Update time- pulled off RRides so some dates might be odd...

On Friday we had some proper decent race car scales at work to weigh the front of the Bedford CF I'm working on so I can get the right springs ordered. I took the opportunity to weigh the Viva...

Now a bog standard poverty spec Viva HB 2 door weighs about 770kg. I have added a heavier rear axle from an HC magnum, heavier larger front discs and calipers, heavier engine and box, heavier seats, heavier widened steels. I have always wondered what the car weighs and I have always guessed it might weigh in at about 850-900 kg. but no- it weighed quite a bit more...

Oh and btw- it came up at almost perfect 50/50 weight distribution. Well without me in it that is..

This weekend should be the last weekend that the Viva will be propelled forwards by two softened triangles spinning away merrily. I will miss it but I'm positive the V6 will be even better (certainly sound better) and I have very itchy engine swappy fingers.

Last night I finished off the spacer that moves the flywheel back 13.5mm. Its a good fit and with that done the conversion of the V6 into RWD configuration is all finished. I now just need to sling it in place and build some engine mounts.

I have been playing with our new ac/dc tig welder. Its top fun! lots to learn but boy its gonna be handy! My first alloy welds, just practicing running beads. My control still isn't there to blend two thin bits together yet but with practice. The messy welds were when a gas hose brass fitting worked loose by the welder. I was wondering what was happening all of a sudden and the heard the argon escaping. ha.

I then thought why not see how the welder handles 10mm thick alloy. I veed the gap out first and then set too. things got pretty hot by the end of it, including me on what was already a hot summer night in the shed. BUt the welder was fine and it almost looks neat. It wont actually be seen anyway but at least now the plate doesn't have a big gap.

I bought a $35 chunk of alloy to make my spacer and then found a chunk big enough behind my tool box. Typical. I had to work carefully with the old lathe as its quite worn out and I don't want any throwout at all with the flywheel.

the spacer all finished.

When I have finished lunch its off to work for the afternoon to finish getting the last things ready before I pull the Rotary out. I have many many things to make and do once the V6 is sitting in place but it will still be a cool place to be just having it mounted there.

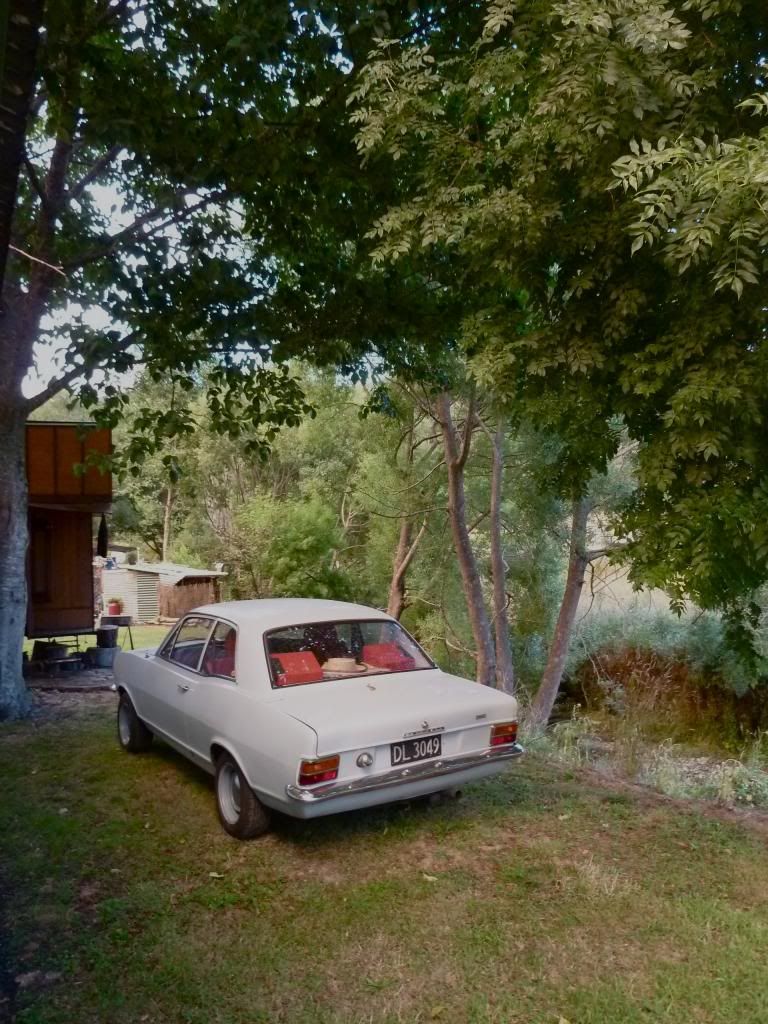

So took the Viva out for last (rotary powered) spin yesterday evening. Met up with Andre who brought out his genuine GT. Had a couple of little races here and there just to confirm to Andre that my little rice powered engine still beats his boat anchor 2.3 slant 4 with big ol' webbers.....

Got some pretty photos.

I'll miss this little engine- it has done 8652 kms completely fault free and never failed to start since last october. Nothing amazing for a modern engine but for a cobbled together old 12A being fed by a carbie turbo its not bad. Still uses curse word all oil. I think its next home may well be Shane's little Ford Anglia- he's the painter at work. Will go bloody well in that!

Today the Viva goes under the knife.

And its out...

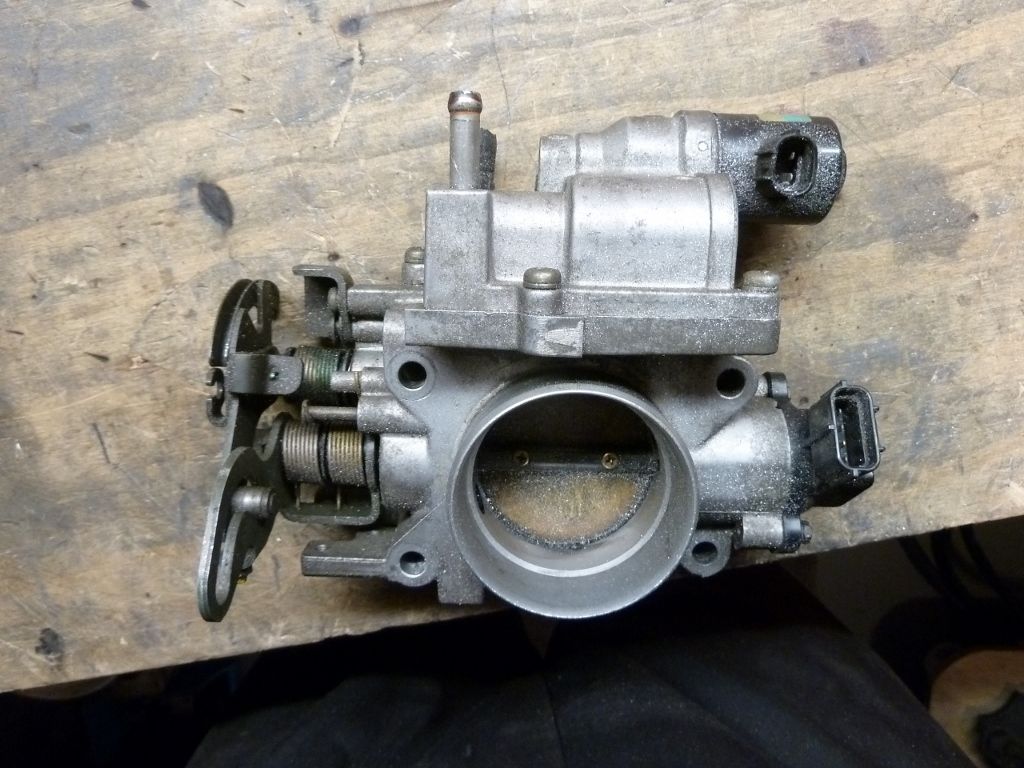

Then in with this.. except I had only loosely done the clutch cover bolts so the input shaft moved the disc so they wouldn't mate up, it was bloody hot, properly bloody sweating wet through hot with a beach only 3 mins drive away and we were running late to look after the olds dogs for xmas. But anyway- it fits without touching the servo- so thats nice.

Oh and looking after the new maine coon girl called Molly- who has the biggest tail I have ever seen on a cat..

The Mazda V6 engine is now sitting happily in the bay. Looks good but is now involving a fair bit more work than I first thought.. I knew it!!! Typical. But its all for the greater good.

Started off this morning by making a proper engine hoist hanger bracket thingee that is adjustable front to back so I can tilt engine. Now much better than silly chain we tried using 3 days ago. With the new EHHBT the engine slid into place with a nice 'thunk' over the input shaft.

This is where I started head scratching. The engine sits lower than thought because the rotary was mounted a bit higher due to its sump. With the engine lower it also seems a bit further forwards than I thought it would be. Plus, due to the g/box bracket being situated about one third along from the rear of box, the box end has gone up as the engine front went down. hmmm- now the prop shaft sits a touch too high.

Hannah and I stood there looking at the vast space between the heads and the bulkhead. My only main reason for not planning on moving the engine further back was because the propshaft would need shortening, the gear lever might end up too far back, the Lh head would hit the servo. But it was just bugging us- all that space. So we set to work before I changed my mind and while Hannah removed the gearstick, carpets and gearbox crossmember I removed the exhaust and propshaft. Then I chopped a big hole out of the tunnel with mr plasma..

..then we pushed the engine back 60mm.

Ahhhh- much better!

I will have to move the servo to the left by about 25mm and to do this neatly I will make a new pedal box layout, chop a silly little bracket away from the bulkhead, strengthening it else where with seam welds and move the servo closer to the bulkhead while I'm at it- to make it tidier a looking area.

I need to make a new brake pedal anyway as the new certifier I'll be using will spot what the last one didn't even look at- the fact that my current brake pedal is made up of two pedals, rx7 and viva, welded together. Welding these parts is apparently a big no no.

So there we have it- now a fair bit more work involved than I had initially planned but that doesn't matter as the engine is now in a better position and so far its still actually falling into place in OK manner- for example..the new gearbox position 60mm further back meant possibly a new crossmember. But I noticed that the crossmember is not straight across and actually has the box mount forwards. So we flipped it around 180 degrees and the box mount still sits right in the middle. And the new gearlever position falls to hand even better now.

The oil filter has a little cooler thing mounted above it. Now the filter sits right over the rack and cant be easily removed. But I was thinking of removing the little cooler thing- its so small I cant imagine it does much? Does it? I think its more of an oil warmer for cold climates and quick warmups maybe? anyway- i'll have more oil capacity with my planned sump mods so maybe that will offset the warmer oil?